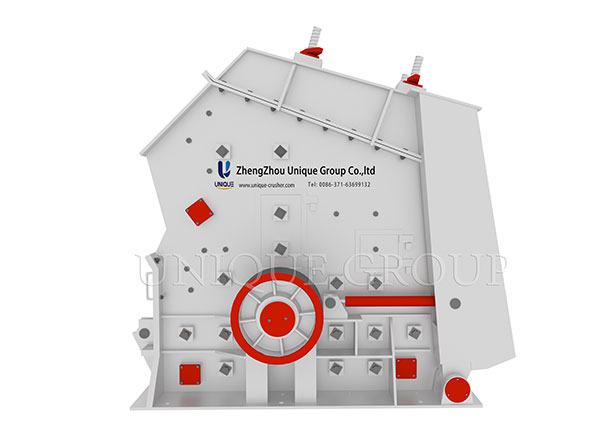

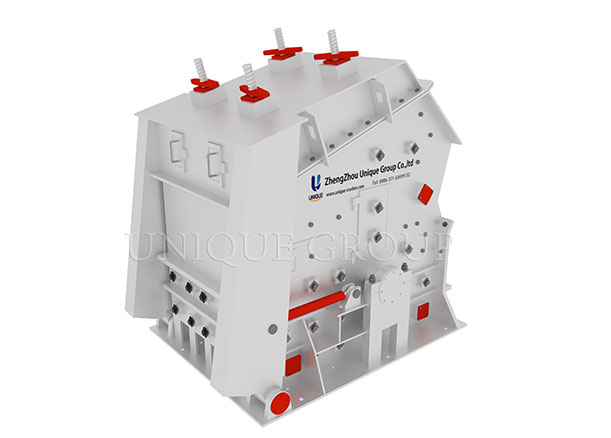

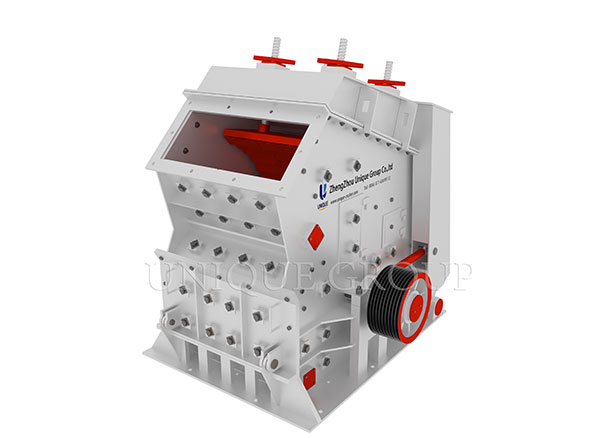

Application of Impact crusher

Impact crusher, a type of impact mill is widely used in secondary crushing in hydropower, highway, artificial aggregate, crushing industries etc. It is applied to crushing materials which is less than 500mm and the compression strength is less than 350 MPa. Regulating the clearance between hammer head, impact plate and balanced parts can adjust the discharging size.

Advantages of Impact Crusher

1. Big feeding opening, high crushing cavity. It is used for crushing high hardness and large lump material, and only producing less stone powder.

2. The design of adjustable clearance between impact plate and board hammer can effectively control the discharging size and particle shape of products.

3. High rigidity, rotor with big moment of inertia.

4. Equipped with shock-resistance and wear-resistance high-chromium board hammer

5. Economic and reliable non-key connection makes maintenance easier;

6. With entire crushing function, high productivity, parts are not easy to be abraded.

7. The final crushed production is in cubic shape.

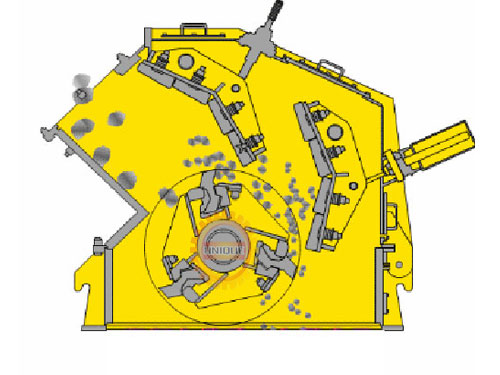

Working Principle of Impact Crusher

When the material was fed into the crushing chamber, impact crusher’s electric motor drives the rotor to reach high speed. The material will be crushed by the plate hammer on the rotor, and then will be thrown to the impact plates, after being crushed repeatedly; the final products will be discharged from the impact crusher.

|

Model |

Rotor Spec(mm) |

Feed Opening Size(mm) |

Max Feed Edge(mm) |

Capacity (t/h) |

Motor Power(kw) |

Weight (t) |

Dimensions (L×W×H) (mm |

|

PF-1007 |

1000×700 |

400×730 |

300 |

30-70 |

45 |

12 |

2330×1660×2300 |

|

PF-1010 |

1000×1050 |

400×1080 |

350 |

50-90 |

55 |

15 |

2370×1700×2390 |

|

PF-1210 |

1250×1050 |

400×1080 |

350 |

70-130 |

110 |

17.7 |

2680×2160×2800 |

|

PF-1214 |

1250×1400 |

400×1430 |

350 |

100-180 |

132 |

22.4 |

2650×2460×2800 |

|

PF-1315 |

1320×1500 |

860×1520 |

500 |

130-250 |

220 |

27 |

3180×2720×2620 |